Descripción

Especially indicated for the purification of wastewater for up to 30 equivalent inhabitants.

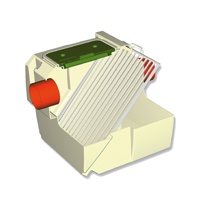

The Imhoff treatment plant is characterized by being compact, resistant, light, easy to handle and being entirely made of high-density polyethylene, achieving a final product without welding, which guarantees liquid containment without the risk of leaks.

ANAEROBIC TREATMENT BY DIGESTION

The Imhoff anaerobic digestion treatment plant does not generate noise.

In a single container, the two purification phases (sedimentation and digestion) are separated by means of two different chambers.

First phase

The wastewater enters the first compartment, where the organic matter (sludge) is decanted.

Second stage

The water passes to a second compartment, where the biological process of decomposition and digestion of organic matter begins, thanks to the anaerobic microorganisms (bacteria) that are formed, which find a culture medium and are responsible for digesting and decomposing the organic matter.

Final score

The purified water without solids is discharged through the upper tube, complying with the limit values of table I of the RDPH (Public Domain Hydraulic Regulations).

If a secondary treatment is then carried out with a trickling filter, the quality of the discharge increases until it meets the limit values established in Table III, the most demanding of the RDPH (Public Domain Hydraulic Regulation). The treated effluent can be evacuated by drainage.

We recommend always pretreating gray wastewater with a grease separator and installing at least one inspection manhole as can be seen in the second image.

COMPOSITION

A single container integrates the two purification phases (sedimentation and digestion)

FUNCTIONING

- The purification equipment is installed buried underground (see instructions). It takes up very little space and requires very little civil work. Polyethylene, being a very resistant and light material at the same time, facilitates both handling and installation, which does not require the use of cranes.

- We recommend placing a siphon before the entrance of each container

- Maintenance is very simple and is done comfortably through the inspection cover, located at the top. Once a year or when necessary, vacuum the deposited sludge, and check that the settler is not clogged.

Important: Do not completely empty the container. Always leave 1/3 of the container

10 year warranty

COMPLEMENTS (Optional)

MOUTH EXTENDER

Step-on extension, made of polyethylene that facilitates access to the manhole

The extension is placed in the Imhoff Biological under pressure and the cap supplied as standard with the purified one is used.

INSPECTION CHART

Square base chest made of monobloc polyethylene with PVC walkable lid

Very practical, ideal as a pipe junction and for inspection and sampling of effluents

ROUGHING GRID

Made of polyethylene, it is placed before the liquid enters the purification equipment. An internal stainless steel grate retains large solid elements and prevents them from entering the equipment uncontrollably, clogging it and causing malfunctions.

It is advised in any situation, although its placement is highly recommended in public places.